A more effective and reliable method of producing battery packs for EVs is required to meet the rising demand in the electric vehicle (EV) industry. Assuring top-tier performance and dependability in electric vehicle batteries requires the correct manufacturing equipment. When it comes to cutting-edge solutions that combine several technologies to boost testing, precision, and production efficiency, LEAD intelligent is way out in front of the pack.

Advanced Camera Test for Precise Battery Manufacturing

At LEAD Intelligent, we understand that precision is key in battery manufacturing. Our electric vehicle battery manufacturing equipment includes fully automatic production lines integrating 3D pad printing, screen printing, and inspection systems. With high-precision visual-guide alignment and AOI (Automatic Optical Inspection) systems, we ensure that each component is perfectly aligned and defect-free. This guarantees that every battery produced meets the highest quality standards.

Camera Image Test for Enhanced Performance Monitoring

Our innovative equipment also includes 40G high-bandwidth, high-speed graphics capture for electric vehicle battery manufacturing equipment. This ensures that image tests are clear and precise, providing critical data for continuous improvement and flawless production. With LEAD Intelligent, manufacturers can optimize the performance and longevity of EV batteries, contributing to the overall success of the vehicle.

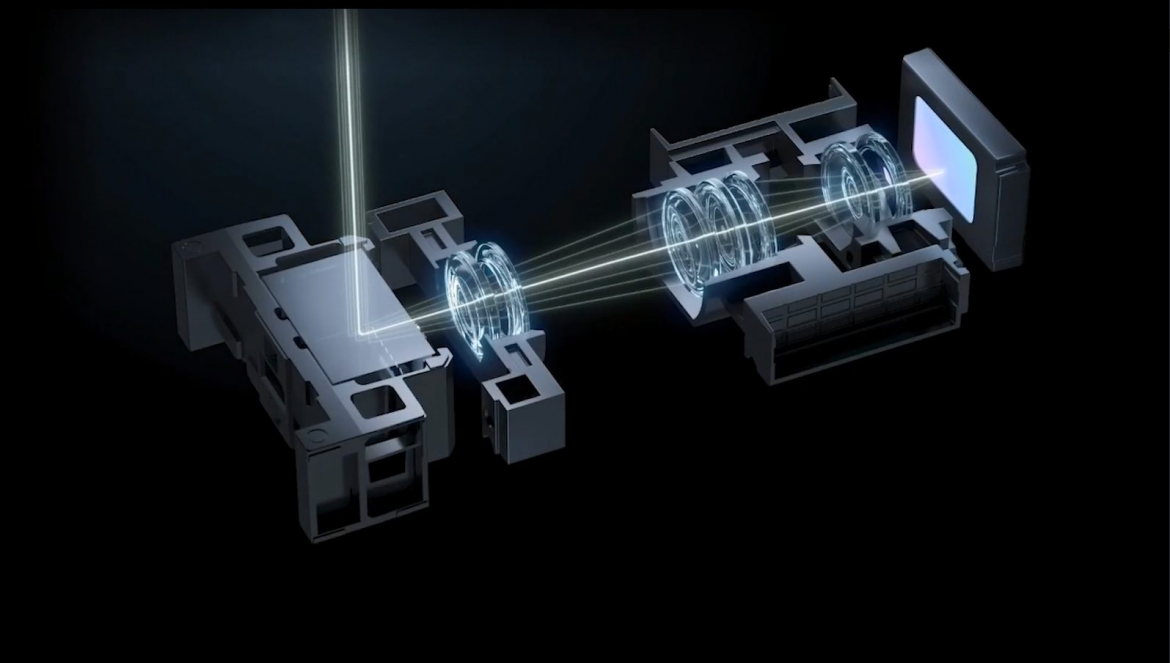

3D ToF Test for Sensor Calibration and Accuracy

LEAD Intelligent also offers a customizable 3D Time-of-Flight (ToF) testing system. This cutting-edge technology includes customizable Tx/Rx sensor detection calibration, ensuring that every battery component is calibrated to perfection. Our electric vehicle battery manufacturing equipment goes beyond just production; it ensures the functionality and reliability of every component through rigorous testing.

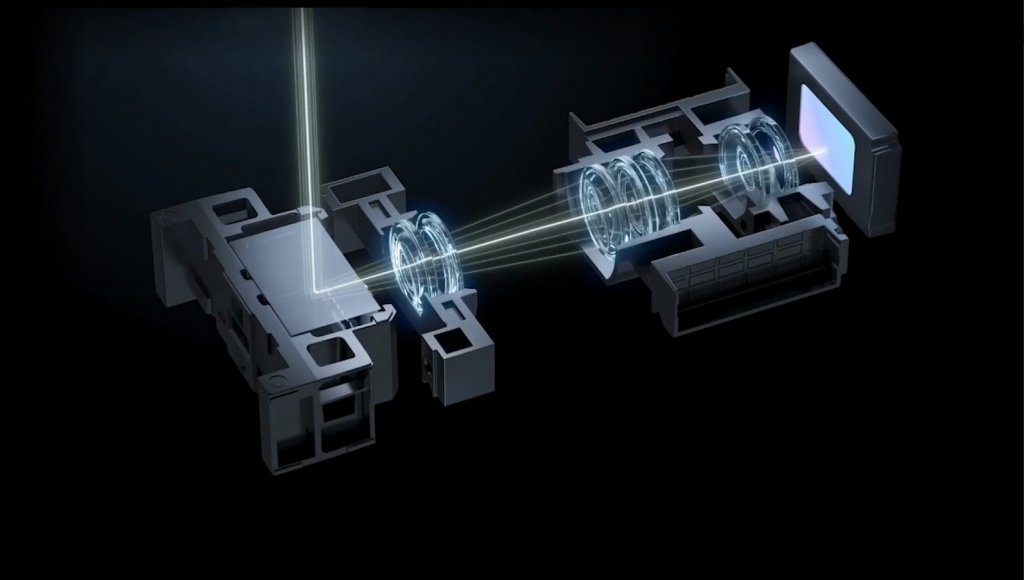

CCM Functional Test for Seamless Integration

Lastly, LEAD Intelligent provides CCM (Critical Component Manufacturing) functional tests, including customizable autofocus, optical buffeting, and color calibration, enhancing the overall manufacturing process of electric vehicle batteries. With our electric vehicle battery manufacturing equipment, manufacturers can ensure optimal functionality, reducing errors and improving efficiency.

Conclusion

In brief, LEAD Intelligent is revolutionizing electric vehicle battery manufacturing equipment by integrating advanced technologies and automated testing systems. With a focus on precision and quality, we’re helping manufacturers produce batteries that power the future of electric vehicles with confidence.